Mechanical Cladding Systems

Cladding Fixation includes design, calculation & production of several types of mechanical fixings & accessories used for cladding purposes. Stainless & galvanized steel are among the various materials used in the fabrication.

Standards:

- ASTM A276 / A276M

- ASTM A666 – 15

- BS 8298-1:2010

- BS 1449-1.1:1991

- BS EN ISO 3506-1:1998

Material:

SS304, SS316, SS316L, SS316TI,

S235JR-MG, S235JR-HDG

Gypsum Profile

Ceiling Suspension Systems & Partitions are considered as an important substitution of ordinary ceiling which is widely used in different locations either indoor or outdoor.

Through the last 30 years Ceiling Systems are going under a lot of improvements and developments year after another depending on the place of usage and the way it is assembled.

Perforated and plain metal tiles in both standard and custom-made sizes are available for both concealed and a variety of exposed grid suspension systems.

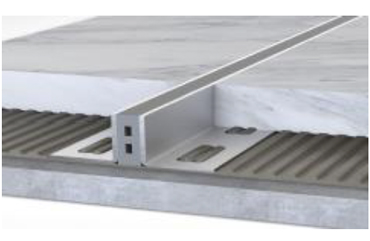

Expansion Joint Cover

Expansion joint cover are designed to accommodate the movement of a building in a controlled manner, preventing damage to the internal and external finishes of a building.

we have a wide range of floor, wall and ceiling expansion joint covers which meet the requirements as per the finishes and load capacity.

Control Joint

Architectural movement/Control joints of various heights and colors available in stainless steel and other bespoke configurations.

Tactile

Tactile pavement is a type of pavement that feature raised lines, domes, or other textures to communicate safety information to people who are blind, have low vision, or another vision impairment.

Studs are designed to act as a stop sign, while strips indicate that a path is safe to walk on.

Laser Cutting & Fabrication

Laser cutting is a precision manufacturing process that uses a focused beam of light (laser) to cut or engrave materials.

The process involves directing a laser beam onto the material's surface, which melts, burns, or vaporizes the material, creating clean edges.

It can be used on various metals steel, stainless steel, aluminum, and Brass. Advantages of laser cutting include speed, versatility, and the ability to automate the cutting process, making it ideal for both prototyping and large-scale production.